The AI-based development method was internally developed by M.TEC and optimizes practically any product, component, and process that can be numerically modeled. The simulation-supported engineering method is most beneficial in new developments, especially when multiple physical parameters are considered simultaneously. Successful product developments prove it!

Typical development scenarios for optimization with AI

Typical development scenarios include:

- Development and optimization towards differently weighted development goals (e.g., a combination of lifespan, reliability, material savings, cost-effective manufacturing)

- Optimization of processes, for example, in terms of stability and efficiency

- Minimization of warpage in injection molded parts

Contact us!

Success Stories and Application Examples

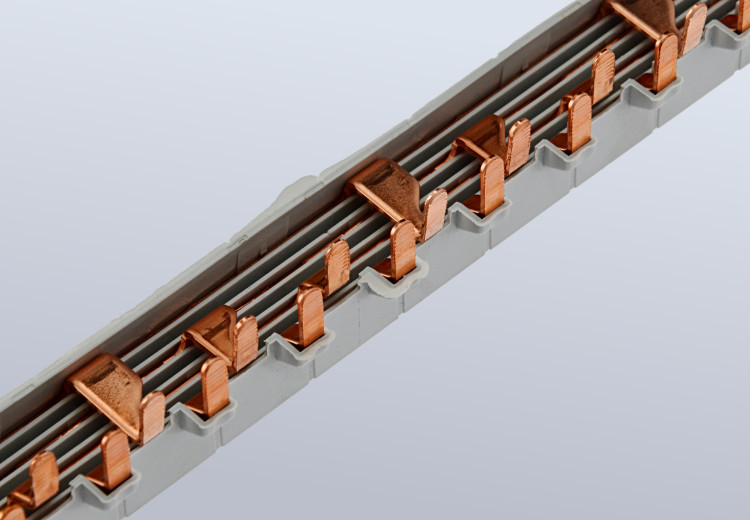

Project example busbar

Project example busbar

Optimization for material reduction, weight reduction and functional fulfillment (current flow, cooling).

Project example insulin pen

Project example insulin pen

Product development suitable for large-scale production that harmonizes precision, safety, quality and patient-oriented handling as well as production costs.

Project example electric motor

Results of the AI-based engineering optimization by M.TEC:

- weight reduction of 17%

- improvement in torque

- increase in service life

- optimization of production

Project example automotive support structure

The AI-based optimization carried out by M.TEC for BMW AG was awarded at the SPE Automotive Award 2021. The following results have been achieved:

- 80% reduction in mold proving time

- significant reduction of material and energy consumption

- elimination of tool changes

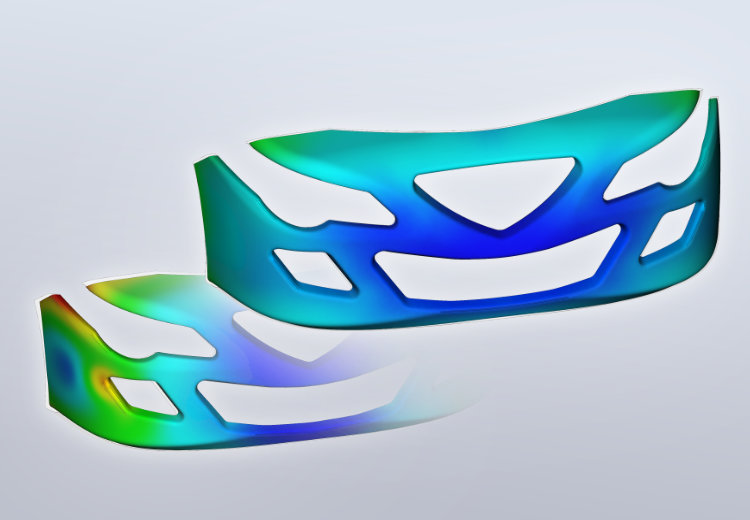

Project example front apron

Reduction of distortion by 45% from 8.0 mm to 4.4 mm and more even residual distortion, weld line-free, suitable for large-scale production (illustrations scaled the same; below before, above after).

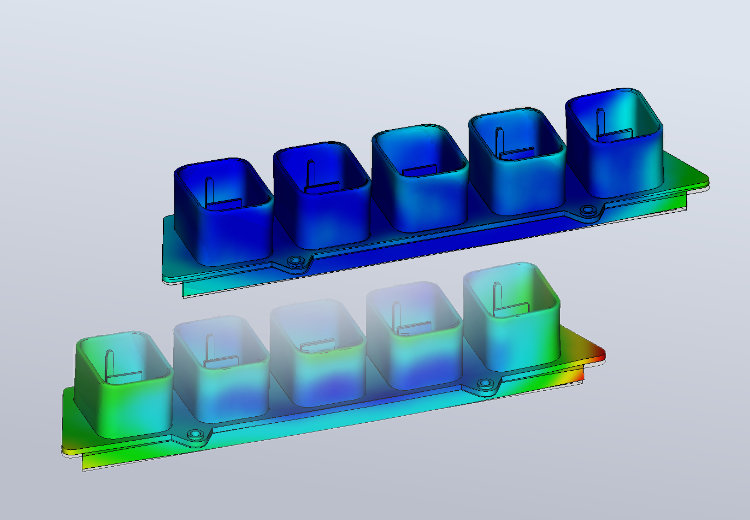

Project example connector strip

Reduction of the total distortion by 36% from 0.461mm to 0.294mm (illustrations scaled the same; below before, above after).

Project example impellers

Project example impellers

Optimization of mechanics (e.g. deformation during operation), fluidic and acoustic properties as well as the injection moulding process (minimizing distortion).

Typical scenarios for design optimization using AI

Typical development scenarios in which the use of AI-based design processes leads to great technical and economic benefits are, for example:

- Critical Products

Design and optimization of critical components and products that must meet the highest quality requirements

- Opposing Development Goals

Design and optimization for opposing, differently weighted development goals (e.g. any combination of long life span, reliability, material savings, cost-effective production)

- Economic efficiency

Minimization of necessary tolerances (“in any case as good as necessary, but not a bit more”)

- Complexity

Design and optimization of particularly complex products, components or parts

- Process Reliability

Optimization of processes with regard to stability, efficiency, etc. (e.g. minimizing distortion of high-end injection moulded parts)

It is a design process that is individually tailored to the respective goals. An intensive, personal exchange in advance is essential. Feel free to contact us without obligation, we look forward to hearing from you!

TISAX-konforme Datensicherheit bei M.TEC

Die KI-gestützte Optimierung bei M.TEC ist TISAX-konform (TISAX ist ein Informationssicherheitsstandard der Automobilindustrie). Die zum Training von KI-Modellen eingesetzten Daten verbleiben vollständig auf den hauseigenen Servern von M.TEC am Unternehmensstandort in Deutschland, was höchste Sicherheitsstandards in Bezug auf die Projektdaten bei M.TEC garantiert. Zudem ist M.TEC seit vielen Jahren ISO9001-zertifiziert.